| HEAD SOCKET COLLET MANUFACTURING RANGE | |||

|---|---|---|---|

| Model | Round | Hex | Square |

| A-15 | Ø 2 mm to 16 mm in step of 0.5 mm. | 4 mm to 13 mm in step of 1.0 mm. | 4 mm to 11 mm in step of 1.0 mm. |

| Ø 1/16" to 5/8" in step of 1/16" | inches size on request | inches size on request | |

| A-25 | Ø 2 mm to 26 mm in ssteo of 0.5 mm. | 4 mm to 22 mm in step of 1.0 mm. | 4 mm to 18 mm in step of 1.0 mm. |

| Ø 1/16" to 1" in step of 1/16" | 1/8" to 7/8" in step of 1/16" | inches size on request | |

| A-30 | AS PER REQUIREMENT | AS PER REQUIREMENT | AS PER REQUIREMENT |

| A-42 | AS PER REQUIREMENT | AS PER REQUIREMENT | AS PER REQUIREMENT |

| A-60 | AS PER REQUIREMENT | AS PER REQUIREMENT | AS PER REQUIREMENT |

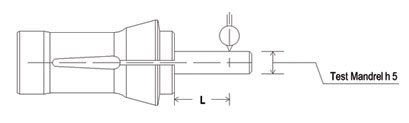

Permissible Concentricity Chart is : 6238 - 1971

| ROUND BORE | ||

|---|---|---|

| Capacity (Bore Size) in mm | Test Lenght L in mm | Permissible Concentricity Error(T.I.R.) |

| above 1 to 1.6 | 6 | 0.02 |

| above 1.6 to 3 | 10 | 0.02 |

| above 3 to 6 | 16 | 0.02 |

| above 6 to 10 | 25 | 0.02 |

| above 10 to 18 | 40 | 0.03 |

| above 18 to 24 | 50 | 0.04 |

| above 24 to 30 | 60 | 0.04 |

| above 30 to50 | 80 | 0.05 |

| above 50 | 100 | 0.05 |

| HEXAGON AND SQUARE | ||

|---|---|---|

| Capacity (Bore Size in mm) | Test Lenght L in mm | Permissible Concentricity Error(T.I.R.) |

| above 4 to 6 | 16 | 0.065 |

| above 6 to 10 | 22 | 0.065 |

| above 10 to 12 | 25 | 0.065 |

| above 12 to 19 | 38 | 0.075 |

| above 19 to 24 | 48 | 0.080 |

| above 24 to 50 | 50 | 0.080 |

| above 50 | 50 | 0.090 |

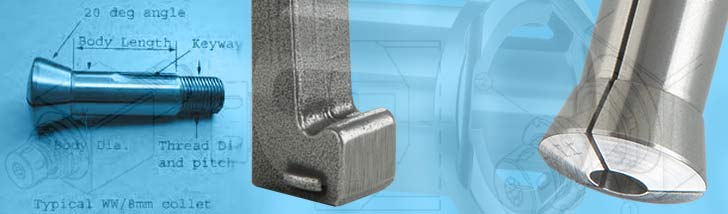

(A) RAW MATERIAL

(B) MATERIAL TESTING

(C) MACHINING

(D) STRESS RILIVING

(E) MACHINING

(F) HEAT TREATMENT

(G) SUBZERO TREATMENT

(H) TEMPRING PROCESS

(I) INDUCTION PROCESS

(J) GRAINDING

(K) SURFACE TREATMENT

(L) WASHING

(M) PACKING & DISPATCHING

Packing Details Goes Here